Maximising Clip Wool Profits with In-shed Micron testing: Use case for Woven Optics to Optimise Clip Preperation.

The Woven Optics technology is well suited for superfine producers looking to increase clip value. A good example of this is the Bolto Family, based in Kangaroo Island, South Australia.

The Bolto family run a 22,000 head Merino wool business, specialising in superfine Merino sheep and currently micron test (side samples sent off-site) approximately 4000 hoggets per year. The average micron of the mob is 16.5, with approximately 40% of the total clip averaging 14.9 micron.

With the Woven Optics Wool Scanner™, the Bolto Family have the opportunity to create a finer clip line at shearing using real-time data and create significantly higher wool returns.

Capturing the True Value of Fine Wool

For many commercial producers, wool is classed based on visual assessment and bulk-tested off-farm. However, this approach often results in:

Missed premium prices as finer wool is mixed with broader microns.

Less control over fleece quality at shearing time.

Increased reliance on pre- or post-shearing lab testing, adding cost and time.

At Bolto Farming, the team wanted to identify and separate the finest 40% of fleece directly in the shearing shed, ensuring they received top market prices for their wool.

Implementing objective in-shed testing for real-time decision making

By adopting Woven Optics’ portable, on-farm micron testing system, Bolto Farming famiy could:

✅ Test fleece instantly in the shed, classing wool with precision.

✅ Separate the finest 40% of fleece, securing higher price premiums.

✅ Make informed breeding decisions, optimising their flock for finer wool.

Increased profits & Efficiency

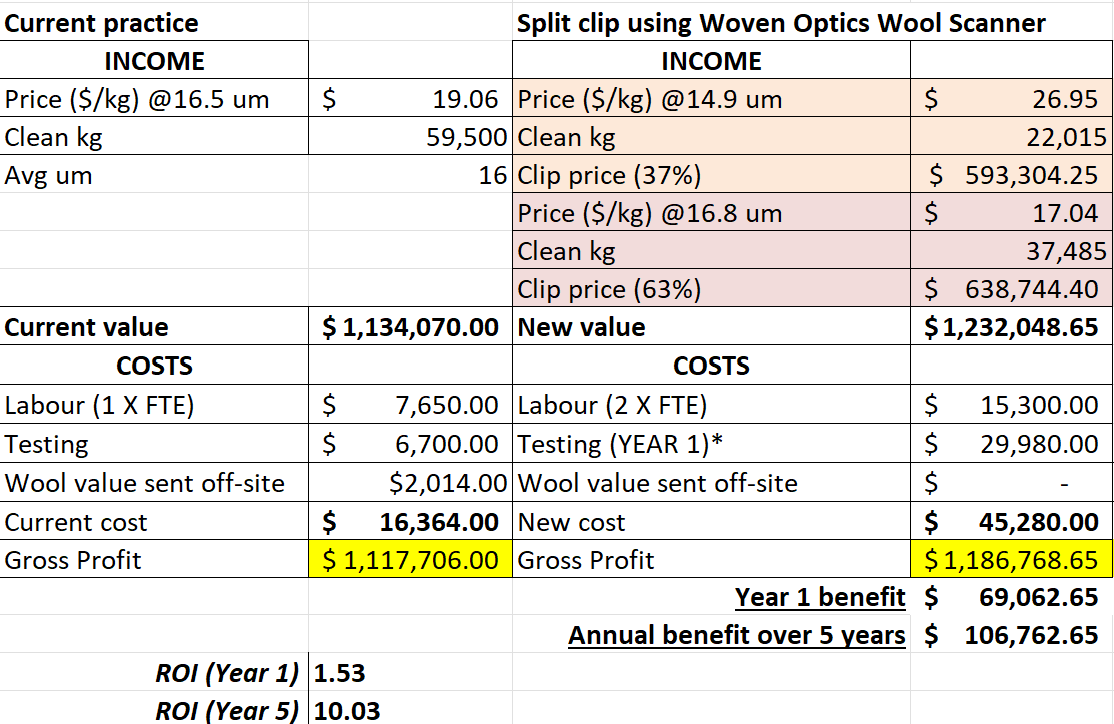

📈 Increased Wool Value: Separated super fine fleece (14.9 um avg) sold at $26.95 per kg (compared to $19.06/kg if mixed, 16um avg), would generate an additional $106,762 per shearing season (amortised over 5 years - ROI: 10.03).

💰 Off-site Testing Savings: Reduce current testing costs by approximately $7500 per shearing session.

⏳ Time Savings: Reduce sorting and testing delays by 7 days per shearing session.

💰 Return on Investment: The system would pay for itself in 1 shearing season - ROI: 2.04, Annual Benefit Year 1: $69,062).

Why Invest in On-Farm Micron Testing?

For Australian Merino wool producers, fine margins make all the difference. With Woven Optics’ portable micron testing, farms can:

✔ Maximize wool returns by securing higher prices for premium fleece.

✔ Reduce processing costs by classing wool more efficiently.

✔ Improve breeding decisions by tracking fleece quality over time.

🚜 Want to see the benefits for yourself?

Contact Woven Optics today and start unlocking the full value of your fleece.

Calculations

Considerations:

This size operation requires 2 (two) Woven Optics units to keep up with a 6-stand shearing shed.

Year 1 cost $7580 (amortised over 5 years, including cost of device & subscription) | *Year 2-5 testing costs reduced to $1980 annually.

Testing labour costs maintained – change of practice from collecting side samples for submitting for laboratory (off-site) testing, to testing on-site.

Wool value differences based on Dec 2024 MPGstyle wool prices (c.f. China-style).

Labour costs calculated as: 1x FTE (1000 fleeces per day 🡺 3500 clean kg) $450 per day.

Current testing costs calculated based on the average number of ewes tested annually @ $1.60 per test (25g sample).

Calculation table model run using indicator type wool (full length, 35 n/ktx).

*Find out how on-farm testing can benefit your business using our own ROI calculator, today!

Author’s note: Values quotes were accurate at the time of writing this article: wool prices, labour cost and sheep numbers can fluctuate throughout and over the seasons, therefore make sure to use the ROI calculator to determine the value to your business based on today’s prices.